AccuTrack CMMS is a state-of-the-art Computerized Maintenance Management System designed by Indusys LTD to streamline your maintenance operations and keep your facilities and equipment in optimal condition. Leveraging advanced technology, AccuTrack CMMS provides comprehensive tracking and reporting features, enabling you to monitor maintenance activities, manage resources, and make data-driven decisions.

With its user-friendly interface and robust functionality, AccuTrack CMMS is the ideal solution for businesses seeking to enhance efficiency, reduce downtime, and maximize productivity. The software's intuitive dashboard presents key metrics at a glance, facilitating quick and informed decision-making.

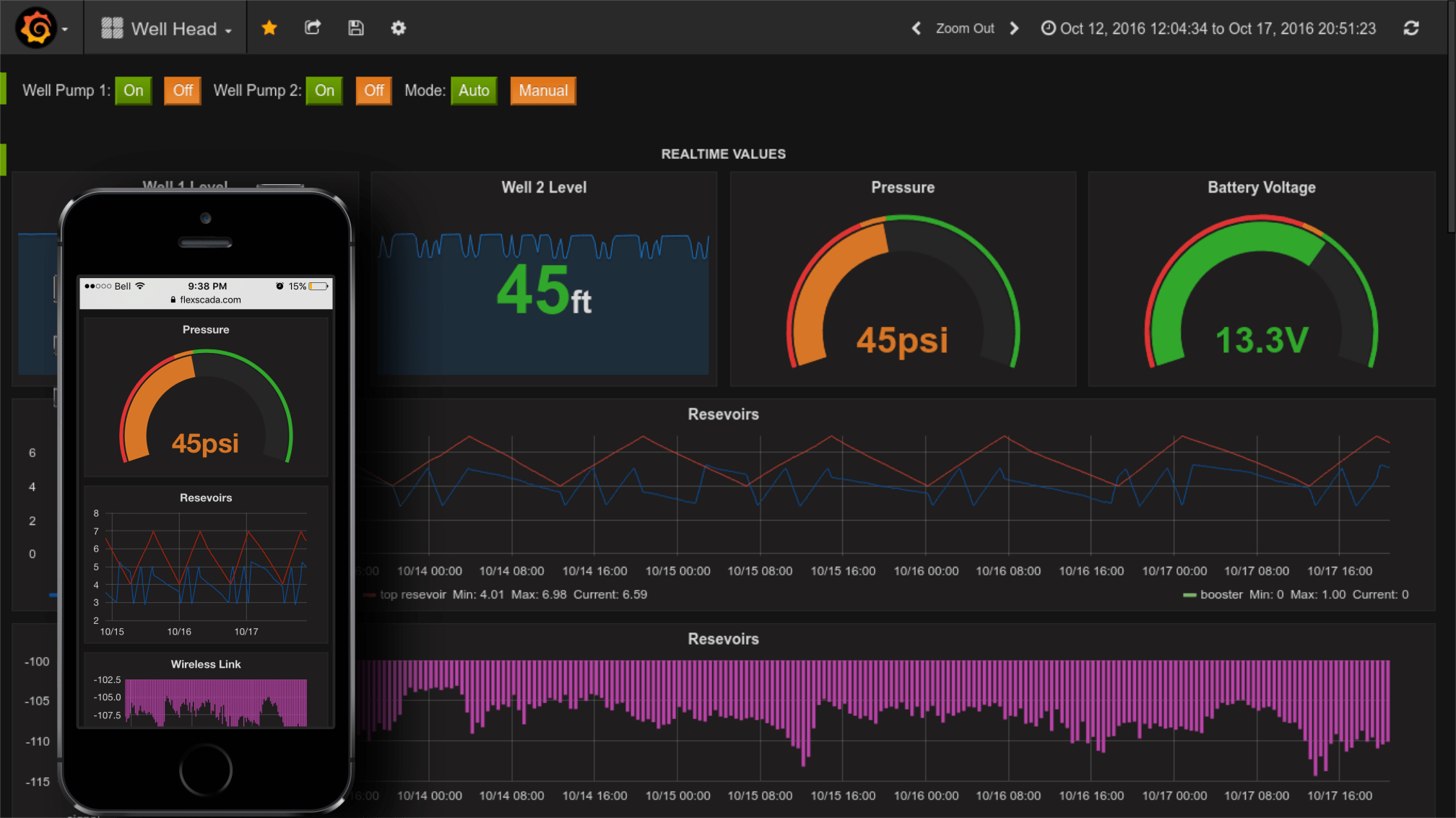

AccuTrack CMMS seamlessly connects to AccuTrack SCADA as an ERP system, creating a unified platform for both operational control and maintenance management. This integration provides:

This integration transforms maintenance from reactive to proactive, enabling you to address issues before they impact operations.

AccuTrack CMMS is designed to operate independently, making it perfect for organizations that need comprehensive maintenance management without SCADA integration. As a standalone solution, AccuTrack CMMS provides:

Whether you're managing a single facility or multiple locations, AccuTrack CMMS adapts to your needs and scales with your operations.

Create, assign, track, and complete maintenance work orders with ease. Support for preventive, predictive, and corrective maintenance strategies.

Comprehensive asset registry with detailed information, maintenance history, and lifecycle tracking. Monitor equipment performance and maintenance costs.

Advanced analytics and ML integration to predict equipment failures and optimize maintenance schedules. Reduce unplanned downtime and extend asset lifespan.

Track spare parts, materials, and supplies. Automated reorder points and vendor management to ensure parts are available when needed.

Comprehensive reporting suite with customizable dashboards. Track KPIs, maintenance costs, asset performance, and compliance metrics.

Full mobile access for technicians to view work orders, update status, log time, and access asset information from the field.

Advanced scheduling tools to optimize maintenance activities, resource allocation, and minimize production disruptions.

Track regulatory compliance, safety inspections, and certification requirements. Automated reminders and documentation management.

Implementing AccuTrack CMMS delivers significant benefits to your organization:

Experts in Industrial Automation

Contact us for all services related to machinery maintenace in SCADA, PLC and VFDs.